Turbine flow meter working principle flowmeasurement december30 2015 brief summary.

Turbine flow meter working principle ppt.

It consists of a multibladed rotor called turbine wheel which is mounted 90 to the axis of the flowing liquid as shown in fig.

Turbine flow meter the fundamental design goal of.

Working principle of turbine flow meter.

The turbine flow meter principle is used for the measurement of liquid gas and gases of very low flow rate.

They will not be linear at reynolds numbers nearing or in the laminar region.

It works on the principle of turbine.

Big money products need very accurate meters.

Working principle types installation and everything else 3 minutes to read the turbine flow meter is one of the most accurate flow meters available and as such one of the most common in fiscal applications such as custody transfer for petroleum.

The typical accuracy and repeatability of turbine flow meters are 0 5 and 0 1 respectively.

The flowmeter is a volumetric measuring turbine type.

Turbine flow meter use a free spinning turbine wheel to measure fluid velocity much like a miniature windmill installed in the flow stream.

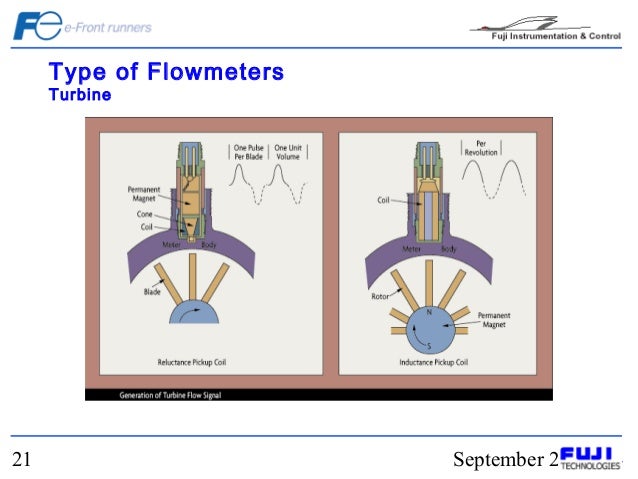

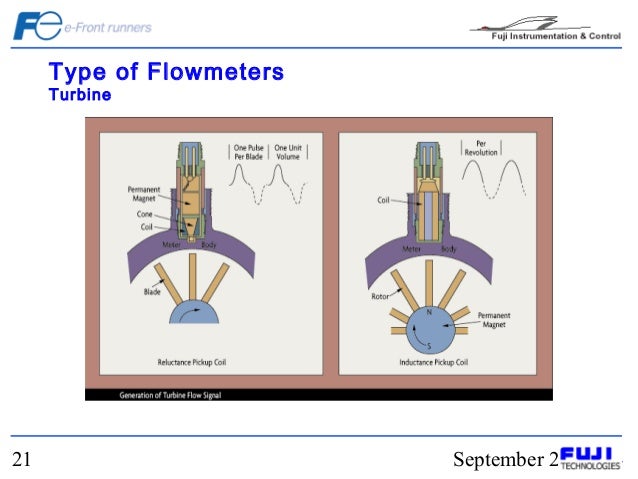

A permanent magnet is encased in the rotor body and each time the rotating magnet pass the pole of the pickup coil working principle of turbine flow meter 118.

However it is possible to achieve accuracy of 0 25 and repeatability of 0 05.

The flowing fluid engages the rotor causing it to rotate at an angular velocity proportional to the fluid flow rate.

The angular velocity of the rotor results in the generation of an electrical signal ac sine wave type in the pickup.

Turbine flow meter turbine flow meter is a type of measurement meter which is use for measure of flow and provide exceptionally accurate and reliable digital outputs.

Turbine flow meters figure 2 are inherently sensitive to reynolds number.

Turbine flow meter is a volumetric measuring turbine type.